After press automation to serve the PVC foil process (membrane or membrane-free) press

- Membrane PVC foil pressed panels trimming machine

- Trimmed foil waste removal and disposal machine

- PVC waste trimmed foil chipping

- Back panel automatic glue residue cleaning machine

SIT TRIM

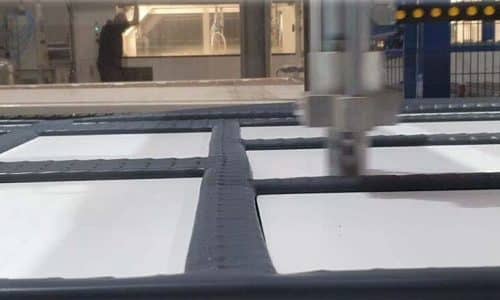

Foil trimming machine with 1 or 2 arms

The trimmer allows the separation of the pressed panels from the foil. This operation must be performed with the utmost precision and care to provide the necessary quality and productivity.

Pallet scanning, due to the extreme specialization, is done by proprietary scanner: either by IR technology or by camera system. The scanning allows the reading and processing of the j-pull doors. As well as any shape and frames.

The machine operation is guaranteed by high performances brushless motors.

The blade arms incorporate a stop safety system in case of blade jamming avoiding further damage to the bed/machine.

The Sittex trimmer is available in different sizes and with 1 or 2 arms according to the press specifications and its cycle time. It is possible to serve more than one press with one trimming line by collecting the outputs/outfeeds with Sittex automation.

Optionals includes the automatic blade change

SIT WES

Trim recovery machine without compacting and chipping

A bar arm system with foil lifting devices, adapted to remove the waste trimmed foil and place it beside the conveyor in a stack.

SIT WES-X

Trim recovery, grinding and storage machine

A bar arm system with foil lifting devices, removes the trimmed foil, which is collected and deposited into a suitable chipper, reducing the volume and/or allowing convenient air management.

With this system the operator’s presence is unnecessary along with the relevant operation of preparing and moving waste bales.

SIT BUFF

Post press residue removing machine from the back side of door

Sittex has studied how to remove the glue residue from the doors back side (typical of the process) without damaging the surface, without delaminating the newly applied foil from the edges and without erasing (even partially) the labels that may have been applied.

A very helpful and cost-saving specialization, allowing the product to always be delivered perfectly clean.

Allows to reduce the manpower needed for this operation and to give a consistently successful result.

3 top brushes driven from dedicated high-power motors grant the best operation performance.